This roller has successfully solved the problem of mechanical waves caused by high counts of spinning, which provides a favorable foundation for superior textile products. Adopting this bottom roller promotes improving the marketing competitiveness of textile products and its exporting business.By increasing textile products’ additional value to improve enterprises’ financial profits, this bottom roller could be installed without presetting, which greatly reduces maintenance and improves efficiency. The technical specifications of this product have reached the world’s top level. Therefore, it can be used as a substitution for the world’s top roller.

Wave Compact Roller Applicable Range

- For the production of yarn≥80 Ne

- For the production of compact spinning yarn

- For the production of other yarns with higher requirement

Features

- Anti-bending strength has been improved by 1% by adopting new craft and materials.

- New technology and craft for the surface treatment, making it smooth without bur or wound

- No need for presetting before bottom rollers are assembled on the machine, only need to link tightly, 98% of each spindle run out range within 02mm, maximum volume ≤ 0.05mm.

- Rate of non-mechanical wave reaches > 98%

- Rate of non-mechanical wave (aka even wave) amplitude reaches > 98%, maximum volume ≤ 3mm

- Improving yarn quality for cotton textile mills and reaching the 5% level of 2013′ s Uster communique

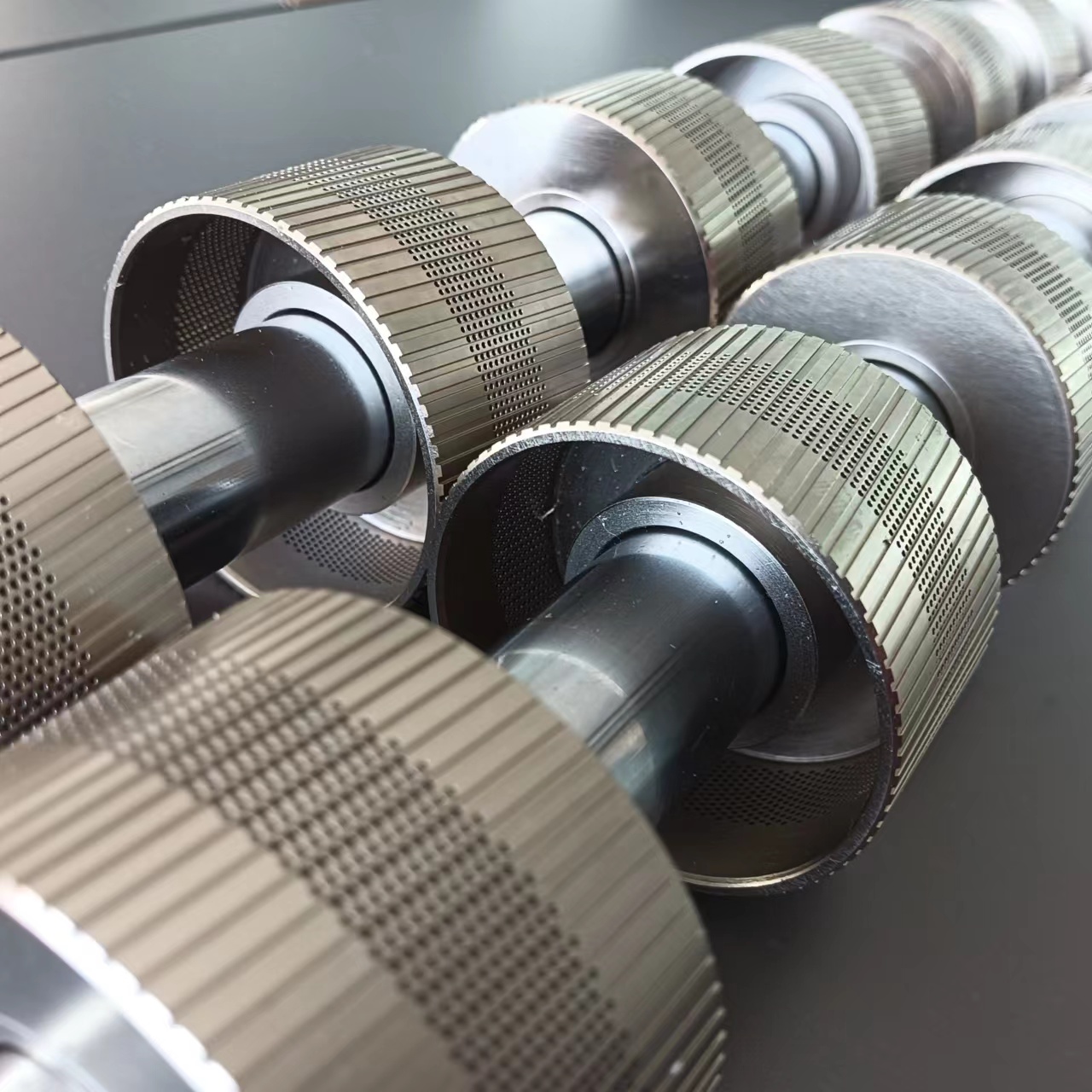

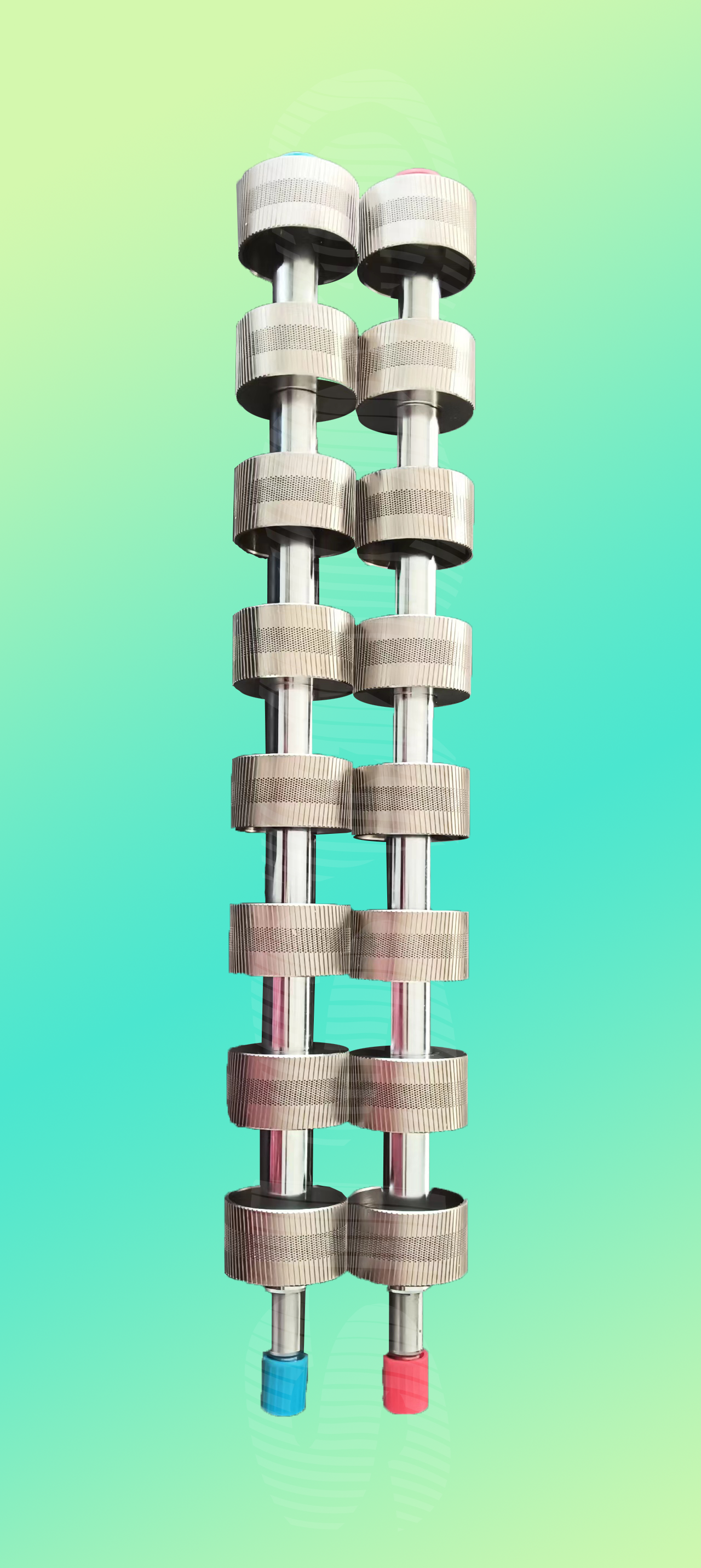

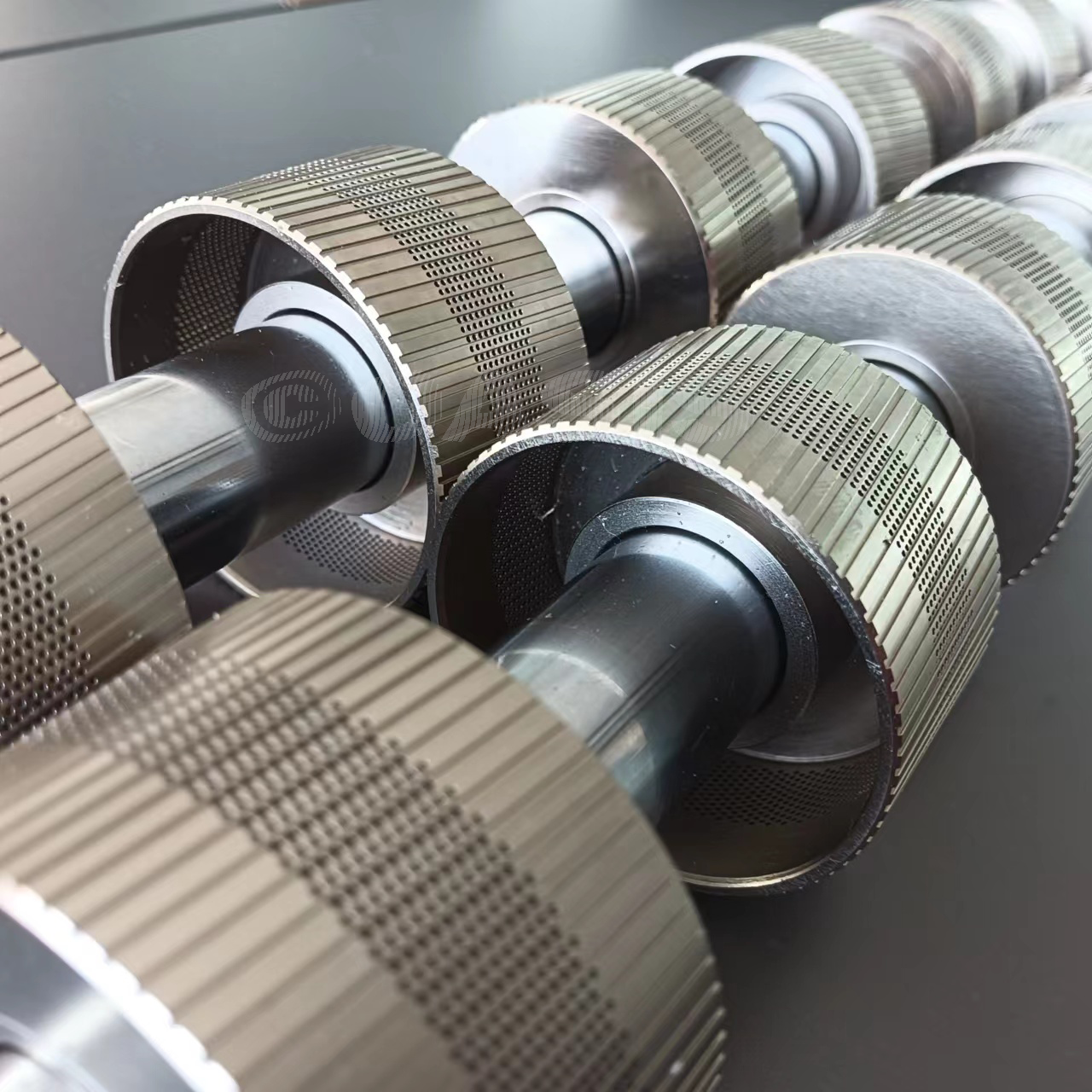

Product Display

The entire production line from manufacturing, examination after each manufacturing alteration, and packaging are regulated by machines, which limits the tolerance interval within 0.015 mm. The reason for our customers’ satisfaction is that our standards are higher than the requirements. Click here to view the manufacturing procedures and environment of our factory 👉🏼👉🏽👉🏾👉🏿 Complete Machinery Manufacture